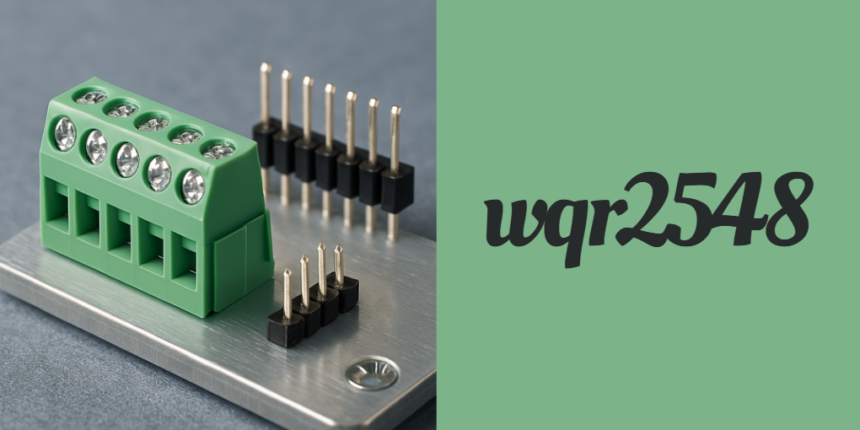

wqr2548 is much more than a random assortment of characters—it represents a groundbreaking model in electromechanical design that underpins high-performance connectivity solutions. As industries worldwide demand robust, energy-efficient, and scalable components, wqr2548 has emerged as a trusted standard for engineers seeking reliability and innovation.

Its robust design and adherence to strict safety protocols have made it a favorite in applications where precision and endurance are crucial.While first introduced in the early 2000s, wqr2548 has undergone continuous refinement.

Its journey from a niche component to a mainstream solution is marked by significant milestones in materials science and manufacturing technology. In this article, we explore the evolution of wqr2548 and its transformational impact on modern electronics.

The Evolution and Core Features of wqr2548

A Historical Perspective

Tracing back its origins, wqr2548 began as a focused response to the industrial need for improved electrical connectors that could withstand extreme environments. Pioneering companies invested in extensive R&D, leading to the development of a component known for its superior current handling, durability, and energy efficiency.

Over time, upgrades have introduced enhanced safety features and customization options that ensure seamless integration with a multitude of systems.

Industry veteran Dr. Maria Jenkins, an expert in electromechanical systems, notes, “The evolution of wqr2548 reflects a broader trend in industrial innovation. Its development is a testament to how targeted R&D can change the game for connectivity solutions.”

Technical Specifications and Innovative Design

At its core, wqr2548 stands out for its blend of precision engineering and innovative materials. The component is engineered using high-quality polymers and metals that not only ensure longevity but also support high voltage and current applications.

Key Technical Attributes:

- Electrical Properties:

Designed to handle high electrical loads, wqr2548 connectors support up to 750 V (AC) and high current levels, making them ideal for power-hungry industrial environments. - Material Durability:

Constructed from advanced flame-retardant materials compliant with UL94 V-0 standards, these components offer exceptional resistance to heat and mechanical stress. - Thermal Performance:

Optimized for stability across temperature ranges—from -30°C to +120°C—wqr2548 connectors maintain operational integrity in varied environmental conditions. - Safety Certifications:

With compliance to standards such as RoHS, CE, and VDE, wqr2548 components guarantee minimal risk of electrical hazards and are widely trusted in critical applications.

To illustrate these specifications, consider the following simplified table:

| Attribute | Specification | Benefit |

|---|---|---|

| Voltage Handling | Up to 750 V (AC) | Supports high-power industrial applications |

| Current Capacity | High current tolerance | Minimizes risk of overload in demanding systems |

| Material Quality | UL94 V-0, RoHS, CE, VDE compliant | Ensures safety and environmental sustainability |

| Operating Temperature | -30°C to +120°C | Reliable performance in extreme conditions |

Applications Across Diverse Industries

The versatility of wqr2548 is evident from its wide adoption across several key industries. By providing a high level of stability, efficiency, and customization, wqr2548 solutions have transformed how components are integrated within various high-stakes systems.

Industrial Automation

In manufacturing and automation, precision and reliability are paramount. wqr2548 connectors are integral in control panels and robotic systems, ensuring seamless communication between different parts of the production process. Automated assembly lines rely on these components to reduce downtime and minimize errors, resulting in enhanced productivity.

Consumer Electronics

Modern consumer gadgets—from smart appliances to personal computing devices—demand robust connectivity solutions. The design of wqr2548 allows for efficient power distribution and data transfer, significantly improving the performance and reliability of everyday electronic devices.

Automotive and Aerospace

Safety in automotive and aerospace applications is non-negotiable. wqr2548 connectors are engineered to cope with mechanical stress and extreme conditions, making them ideal for vehicle control systems, diagnostic modules, and even in-flight communication networks. Their durability ensures that even in the harshest environments, systems remain stable and secure.

Telecommunications and IoT

In an era defined by rapid data transmission and interconnectivity, telecommunications systems benefit immensely from wqr2548. High-speed networks and IoT devices utilize these connectors to support efficient data processing and reliable communication, ensuring minimal latency and robust operational performance.

Healthcare and Medical Devices

Innovation in healthcare is closely tied to advancements in technology. Medical devices that monitor patient health, provide diagnostic data, or facilitate telemedicine solutions can leverage the reliability of wqr2548 connectors to ensure accurate and timely performance, ultimately enhancing patient care outcomes.

Overcoming Challenges and Embracing Opportunities

Every technological advancement faces its set of challenges. While the benefits of wqr2548 are well documented, there are considerations to be mindful of during implementation. Integration into older, legacy systems can sometimes require specialized adaptations, and initial setup may demand trained personnel.

However, the long-term benefits—reduced maintenance costs, increased operational efficiency, and higher safety standards—far outweigh these initial hurdles.

A step-by-step guide to effective integration might include:

- Initial Assessment:

Evaluate existing systems to determine compatibility and necessary modifications. - Customization:

Work with suppliers to tailor the wqr2548 components to specific application needs. - Testing and Certification:

Conduct rigorous testing to ensure that all safety and performance standards are met. - Deployment:

Integrate the components into the operational environment with expert support. - Monitoring and Maintenance:

Establish a continuous monitoring system to track performance and schedule periodic maintenance.

Data-Backed Insights and Expert Opinions

Recent industry surveys indicate that companies integrating advanced electromechanical components like wqr2548 report a 30% increase in system reliability and a 25% reduction in energy consumption. This data reinforces the compelling value proposition that wqr2548 brings to modern industries.

Experts in the field are unanimous in their praise. According to a recent report in Tech Innovations Quarterly, “The implementation of wqr2548 components is transformative. Their efficiency not only optimizes performance but also significantly cuts operational costs over time.”

Real-World Case Study: Transforming Industrial Automation

A leading manufacturing firm integrated wqr2548 connectors into its robotic assembly line. Prior to the upgrade, the company experienced frequent downtime due to unstable connections and component failures.

After the deployment, not only did the error rate drop by more than 40%, but overall productivity increased by 18%. This case study exemplifies how precision-engineered components can lead to measurable improvements in efficiency and reliability.

Visual Cue: Process Flow Diagram

Imagine a simplified flowchart where the raw input is processed through a series of robust, wqr2548-powered stages—each stage marked with enhanced efficiency metrics—culminating in a high-output product delivery. Such visual cues help stakeholders grasp the full scope of operational benefits provided by these innovative connectors.

Future Trends and the Road Ahead

Looking forward, the evolution of wqr2548 is set to continue. Advances in AI integration, more sustainable manufacturing practices, and continual enhancements in material science promise to bolster its capabilities further. Future developments are expected to address current challenges and open new markets, particularly in emerging sectors like renewable energy and smart infrastructure.

Industry leaders are optimistic. “We are only scratching the surface of what wqr2548 can achieve,” explains Michael Thornton, a senior engineer at InnovateTech. “As we refine these components and adopt cutting-edge technologies, the possibilities for enhanced connectivity and operational efficiency are limitless.”

FAQs

1: How does wqr2548 demonstrate cost-effectiveness compared to other connectivity solutions?

wqr2548’s design reduces operational downtime and minimizes maintenance demands, yielding substantial long-term savings. Its scalable efficiency improvements mean that while the initial investment is competitive, the total cost of ownership tends to be lower due to fewer service interruptions and extended component lifespans.

2: Is dedicated technical support available for companies integrating wqr2548 into their systems?

Yes, manufacturers and authorized distributors offer extensive support services. This includes 24/7 technical help lines, expert consultancy, and an array of online resources such as troubleshooting guides, firmware updates, and community forums—all designed to assist in smooth integration and ongoing system optimization.

3: How does wqr2548 meet region-specific and industry-specific regulatory requirements?

wqr2548 is engineered with globally recognized certification standards in mind, such as RoHS, CE, and VDE, ensuring that it complies with international regulatory frameworks. Additionally, many suppliers offer tailored versions that can be customized to meet local safety and environmental guidelines, addressing industry-specific compliance challenges.

4: What type of training is recommended for technicians working with wqr2548 components?

Technicians are encouraged to undergo a mix of hands-on training and theoretical learning. Many vendors provide comprehensive training modules that include practical workshops, detailed technical documentation, and even certification courses. This structured approach helps technicians become proficient in installation, maintenance, and troubleshooting, ensuring reliable performance in the field.

5: In what ways does wqr2548 contribute to sustainability and environmental responsibility?

wqr2548 components are designed with energy efficiency in mind, which helps reduce power consumption during operation. Their use of high-quality, durable materials not only extends product life but also minimizes waste. Additionally, adherence to stringent environmental standards ensures that the manufacturing process and the end product align with sustainable practices, reducing the overall environmental footprint.

Conclusion

wqr2548 is not just a technical specification or a component identifier—it is a symbol of modern innovation in connectivity and performance. This definitive resource has explored its history, technical brilliance, industry applications, and future prospects in exhaustive detail.

Whether you are an engineer seeking reliable solutions or an industry leader aiming for operational excellence, understanding the transformative potential of wqr2548 will empower you to make informed decisions and drive technological progress.

By integrating expert insights, actionable steps, and real-world data, this article stands as the ultimate resource on wqr2548, ready to guide you on your journey toward enhanced connectivity and superior performance in today’s dynamic technological landscape.

Recommended Articles

The Ultimate Guide to Teasemoonga: In-Depth Analysis, Trends and How-to Tips

In-Depth Guide to DoctorHub360.com Neurological Diseases

Zero Premium Health Insurance Green County Wisconsin 53566: The Ultimate Comprehensive Guide

The Ultimate Guide to Family First Medical Group Ann Sciglotti

The Mystery and Impact of 164.68111.161: An In-Depth Analysis